Electricians often refer to it as a 5mm cable.Īuto cable like the SCA example above also uses the 5mm cable terminology.

#Automotive wire gauge chart iso#

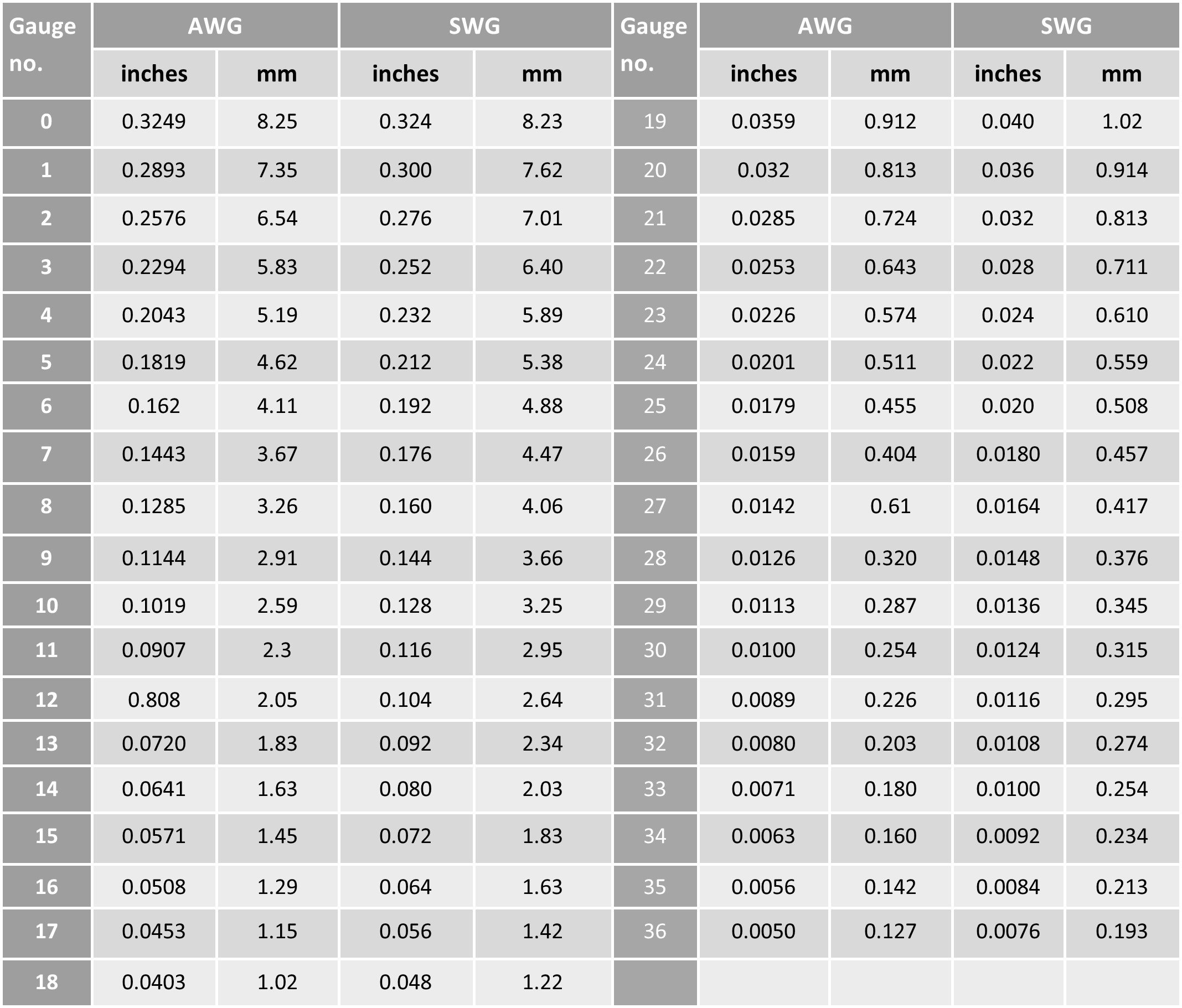

A 5 ISO cable for example, has a cross-sectional area of 5mm 2 (or sq mm). Now, there’s a commonly used standard called the ISO Standard.

#Automotive wire gauge chart plus#

the 5mm refers to the diameter of the cable plus the insulation. You’ll see in the image above, it says “Size: 5mm (2.90mm 2)”. An example of auto cable, showing typical information they might provide. Obviously the cable carries the current, so the cross-sectional area of the copper wire is super-important when you’re trying to size a cable.īut there’s a problem with how auto cable is labelled. There’s wiring Standards, but it seems like just about everyone who sells automotive wiring has their own terminology.īe really careful. It’ll at least give you an indication of the cable’s size.Īuto cable sizing is a mess in this country. If you can’t measure an individual strand, then measure the diameter of the bundle. Go down one cable size when you do this.Enter overall diameter of copper bundle in “Diameter of one strand (mm)”.Enter 1 in “Number of strands in cable”,.Just make sure you go down a cable size if you do this. It’s not as accurate but will give you an indication at least. If measuring a single strand is too difficult, measure the diameter of the whole bundle. Measure one strand with a set of verniers, then count the number of strands. Enter these two figures in the Calculator, and you’ll get the Cable Area in sq.Measure the diameter of a single strand (not the whole bundle of strands which make up the cable) or get this information from the cable supplier’s website.Use the calculator below to figure out the cross-sectional area of the cable, then use the Cable Size Chart to match it to the nearest size. What if you already have cable, but have no idea what size it is? Always go to the next cable size up.Ĭlick here to go back to Cable Size Calculator.įiguring Out What Size a Cable Is – Another Handy Calculator Use this to find the right cable in the Cable Size Chart. You might decide this is acceptable or you might decide to increase the cable size for your fridge supply.Ħ. Then 5% of the power produced by the solar panel is simply generating heat in the cable. Say you’re losing 5 Watts through your fridge cable, and say your solar panel is producing 100 Watts and powering your system. If nothing else, this value gives you an idea of how much power you’re losing in your cables. This is why small cables melt when you blast a high current through them. The lower the voltage drop, the less heat generated. Voltage drop gets converted to heat in the cable. So use 0.36 volts for smaller cables (6 AWG/16 ISO and smaller) and 0.24 volts for large cables (4 AWG/25 ISO and larger). Why? Because they won’t heat up as much and the power loss will be lower (see below). It’s a good guide.Ġ.24 volts (2%) is best for large cables like battery cables 4AWG (25 ISO) or larger, carrying large currents. This allows for a 3% voltage drop through the cable, which is acceptable for most automotive wiring jobs (3% of 12 volts = 0.36 volts). 0.24V for 4 AWG & 25 ISO cables and larger.”. 0.36V for 6 AWG & 16 ISO cables and smaller. You’ll notice under the Voltage Drop box it says, “Max. This is the total voltage drop from one end of the cable to the other. Allow for this now, rather than rewiring it later. So the maximum current through the supply cable is (40+10) 50 Amps.Īnd keep in mind you might want to add something later. Off the terminal box you have a compressor with a maximum current draw of 40 Amps and a fridge with maximum current draw of 10 Amps. Say you have a terminal box and want to size the supply cable. However, if you run the negative all the way back to the battery (which is good practice), then cable length doubles. If you run the negative to ground from the compressor at the compressor, then total cable length is 2 metres (plus a bit for the negative cable). Say you run a positive cable from the battery to a compressor. This is self-explanatory… except it’s not. It’s an estimate, don’t be too worried about getting it spot-on. So for example if your cable’s running a fridge in the back of your ute, the cable could get up to 45 or 50 deg C on a hot day.

If you’re running a cable from a battery under the engine bay, it can get pretty hot… like 70 deg C or more. The hotter the cable, the more voltage drop through the cable.

0 kommentar(er)

0 kommentar(er)